A technician analyses the available solutions to choose the most suitable gearmotor, based on a technical drawing of the industrial plant.

Introduction

Choosing the right gearmotor is essential to ensure efficiency, durability and optimum performance in any industrial plant. In this article we guide you through the main types of Automec gearmotors and help you understand which one is right for you.

Questions to ask yourself before choosing:

- What is the required torque?

- What sizes are available?

- What kind of movement needs to be generated?

- What are the environmental conditions (temperature, humidity, dust)?

- Is an irreversibility of the movement necessary?

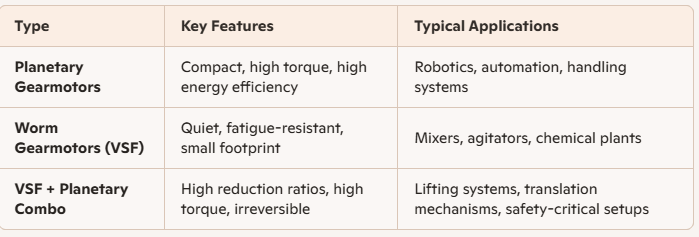

Automec gearmotor types and their applications.

Each type has specific advantages, and the choice depends on the type of work to be done and the operating conditions.

The advantages of Automec customisation

Automec does not simply offer gearmotors: it offers tailor-made solutions. That is why choosing Automec means investing in reliability and performance:

- Decades of experience in complex and international projects

- Customised design for every need

- Direct dialogue with the customer to understand real needs

- In-house production certified to ISO 9001:2015

Case Study: Martens Cleaning – Nature Group (NL)

A concrete example is the collaboration with Martens Cleaning, a company specialising in industrial washing systems. This Dutch company operates internationally and therefore needed a good, effective and durable solution. The application required a compact, silent and moisture-resistant gear motor to be integrated into a mobile DPF filter cleaning system. The company therefore turned to Automec to find a suitable solution.

Automec has designed an EP35 planetary gear motor with specific features:

- Small dimensions: 35 x 35 mm body, ideal for limited spaces

- Lubrication for life: no maintenance required

- Self-lubricating materials: long life and high reliability

- Possibility of plastic gears to reduce noise

- Gearbox output shaft with drill hole to suit system geometry

The EP35 planetary gear motor chosen by Martens Cleaning compact, reliable and custom-designed by Automec for industrial cleaning applications.

The result? A reliable, efficient and perfectly integrated system in the Martens machine, with superior performance compared to previous solutions.

Conclusion

Choosing the right gearmotor is not just a technical question: it is a strategic decision. With Automec, you have a partner at your side who accompanies you from design to implementation, with tailor-made solutions and consolidated know-how.

Do you have a particular application? Contact us: the next customised project could be yours.